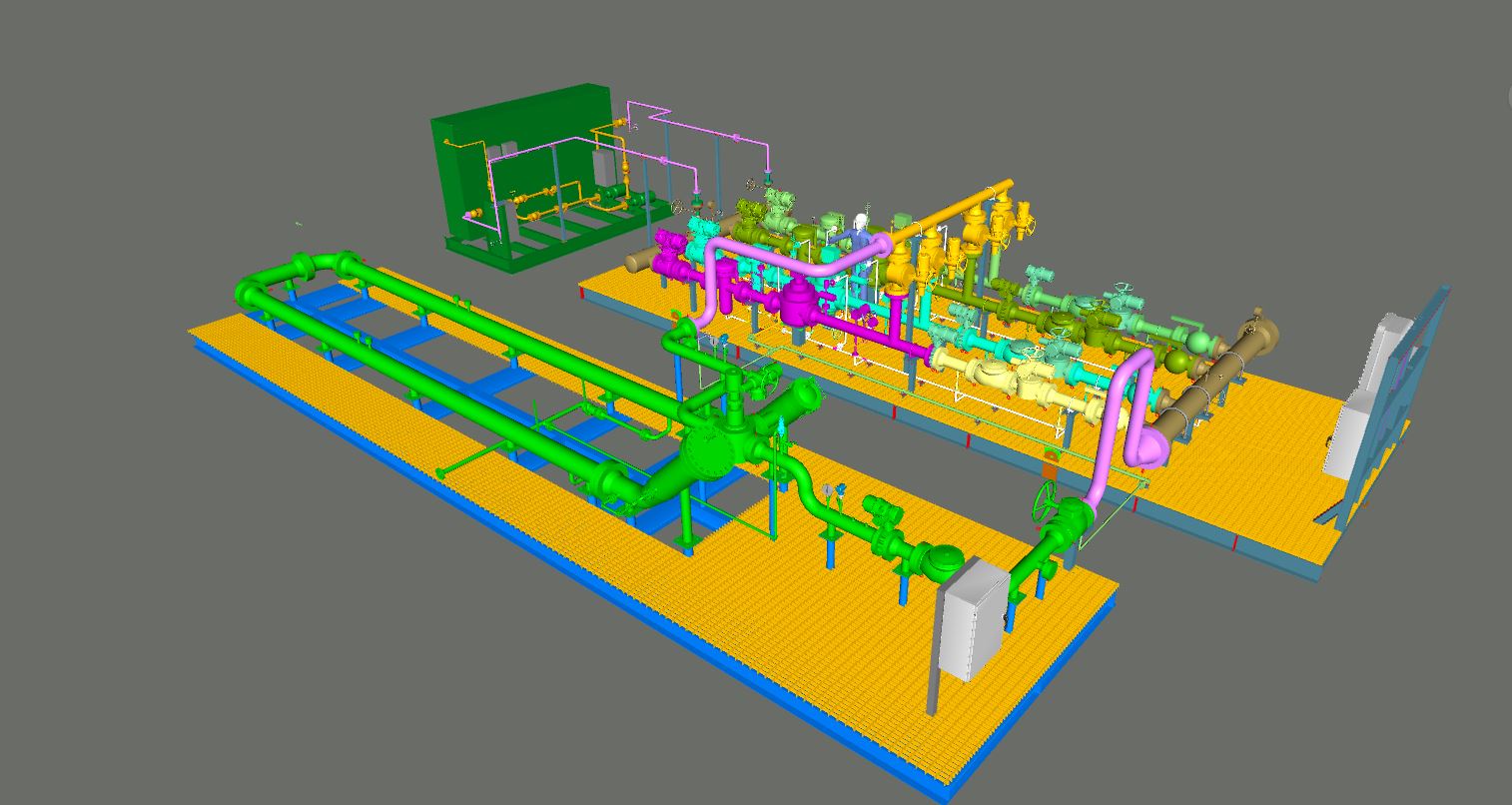

Metering Systems

Metering systems can be designed with a variety of flow meters such as Orifice Meters, Positive Displacement (PD) Meters, Ultrasonic Meters, Coriolis Meters, and Turbine Meters. Our systems are equipped with a Programmable Logic Computer (PLC) with HMI and instrumentation to conduct a variety of measurements with: Densitometers, Gas Chromatographs, or others for testing basic sediment and water (BS&W), temperature, and pressure. Our instrumentation can be pre-programmed to adjust calculations to compensate for differences in temperature, viscosity, and density to report details within any accuracy range dictated by local jurisdictional guidelines and industry standards (American Petroleum Institute’s (API), Manual of Petroleum Measurement Standards (MPMS), or International Standards Organization (ISO) TC28 standards).

Integrated provers and samplers are standard.